3D Printed houses - Fad or Future?

The world is experiencing a housing crisis. Urbanization and population increase have exacerbated housing challenges in many cities throughout the world. At least 1.6 billion people worldwide do not have suitable housing.

The situation is only going to get worse, as UN-Habitat estimates that by 2030, over 3 billion people will require suitable and affordable housing. It claims that the only way to meet this demand is to build 96,000 new homes every day. So, how do countries deal with this problem?

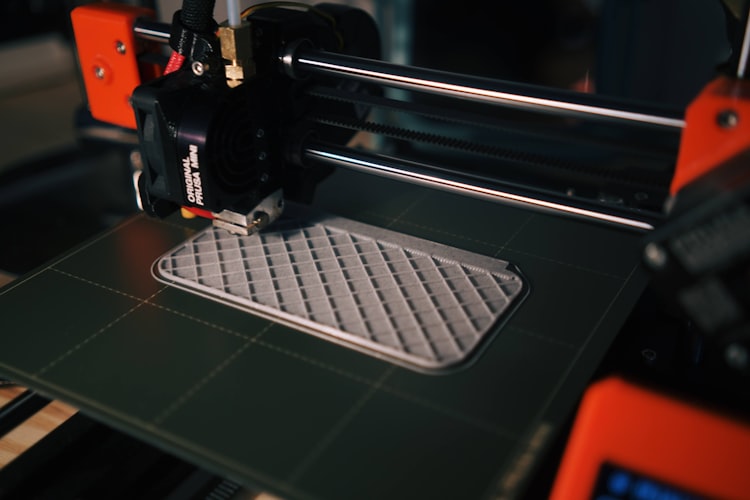

This relatively new technology is steadily changing the face of building, which many people are unaware of. You may have heard about how 3D printing is being used in a variety of areas, including healthcare and manufacturing. It is, however, now venturing into the construction industry.

Buildings are taking on a new look thanks to 3D printing. It's been heralded as a game-changer in terms of affordable and sustainable housing.

Consider this: Instead of the weeks or months it takes to build a house using standard methods, you might have your home completed in as little as two days. And it's not just any house; it's a new, contemporary home for a fraction of the cost. It's as simple as picking a design and pressing the print button.

Icon, a building technology startup based in the United States, is already employing this technology to help address housing affordability for the lowest members of society. The business, based in Austin, Texas, made news in 2018 when it built the first approved 3D printed home in the United States. For less than $4,000, the house was erected in less than 24 hours.

3D printing, according to Jason Ballard, co-founder and CEO of ICON, can save building costs by up to 30%.

The firm employs a printer known as Vulcan, which can manufacture a 350-square-foot home blueprint in only one day. A nozzle on the printer may extrude concrete or other building materials. It builds walls from the ground up to make a three-dimensional structure the size of a house.

Vulcan prints the complete house on-site and produces almost no trash. Other materials, such as windows, wiring, and doors, are provided by Icon's partners at Alchemy Builders. A structure like this can be built for as little as $4000.

Because much of the building is automated, a 3D-printed house only requires a few laborers on-site. A 2,000 square foot house, for example, would require less than five employees, as opposed to the over 20 manual laborers required at traditional construction sites.

“Conventional construction methods have many baked-in drawbacks and problems that we’ve taken for granted for so long that we forgot how to imagine any alternative,” Ballard says.

“With 3D printing, you not only have a continuous thermal envelope, high thermal mass, and near zero-waste, but you also have speed, a much broader design palette, next-level resiliency, and the possibility of a quantum leap in affordability. This isn’t 10% better; it’s ten times better.”

Aside from lower prices, decreased labor, and faster construction, 3D printing technology also provides new building alternatives that would otherwise be prohibitively expensive using traditional construction methods. It encourages creativity and innovation by allowing the production of complex shapes and structures with ease.

A 3D printer, for example, can make an intricately curved wall in the same way that it can create a straight one. Similarly, 3D printed houses are more durable because the structures adopt the shape of curved forms rather than the traditional rectilinear forms, adding stiffness.

Icon has created 24 3D printed homes in the United States and Mexico to date. The residences in Mexico were built as a result of a collaboration between the company and New Story, a housing non-profit. The goal in all situations was to address the rising rate of homelessness.

Aside from the United States and Mexico, 3D printing success stories have been witnessed in other nations. A Dutch couple has become the first occupants of a totally 3D printed house in the Netherlands. The boulder-shaped concrete house was produced as part of Project Milestone, a five-home 3D printing program in Eindhoven.

It is considered to be the first legally livable 3D-printed home in Europe. To blend in with its natural surroundings, the single-story structure was meant to approximate the shape of a boulder.

In other news, India opened the country's first 3D printed house in late April 2021. The house, designed by TVASTA Manufacturing Solutions, was erected in just five days and is anticipated to be 30% less expensive to construct.

“Traditional construction is tedious and time-consuming, and people are increasingly getting left out as affordability is limited, or settling for low-quality homes,” said Adithya Jain, Tvasta’s co-founder and CEO.

“With 3D printing, we can ensure good quality housing that is affordable and resilient to disasters such as earthquakes and cyclones that people in low-quality homes are more vulnerable to,” he added.

Without a question, this game-changing technology is gaining traction around the world. It is slowly but steadily giving traditional builders a run for their money because it is more efficient and twice as fast. 3D-printed houses are not only economical, but they are also environmentally benign, making them a viable option for long-term dwelling.

The construction business is one of the few industries that is thought to be resistant to technological advancements. Alexandria Lafci, New Story's COO, describes it as the world's "least digitized, least inventive" industry. However, as the old adage goes, you can't put a halt to a good idea.

3D printing appears to be an appropriate answer for dealing with the world's persistent housing deficit.

“The magnitude of the problem that we face is so big, it’s about a billion people that don’t have one of life’s most basic human needs, and that’s safe shelter,” says Brett Hagler, founder and CEO of New Story.

He goes on to say that by merging 3D printing into construction, an entire town could be constructed in a matter of months. “That has to come through significantly decreasing cost, increasing speed, while doing that without sacrificing quality.”

Sources:

homelessworldcup.org

unhabitat.org

3dprintingmedia.network

greenmatters.com